Page 2 - ZSi-Foster Cut Strut

P. 2

Wesanco Material &

®

Finish speciFications

General Information Finishes

Most Wesanco channels are produced in 10 and 20-foot lengths with Electroplated Zinc or Electro-Galvanized (EG)

1

a length tolerance of plus or minus ⁄16. Wesanco W700 and W6500 This coating is standard for most ZSi-Foster products. Electro-

are produced in 10 foot lengths only.

Galvanized products meet ASTM B633 SC1 or SC3, Type III.

Channels Electroplating deposits zinc on the surface of the steel by electrolysis

from a bath of zinc salts. The thickness of zinc applied in this method

General is between 0.2 mils to 0.5 mils [5.1 µm to 12.7 µm].

Wesanco channels are manufactured by the cold roll forming Mill-Galvanized (Pre-Galvanized) (PG)

process which produces cross sections of uniform dimensions ASTM A653 G-90 Pre-galvanized zinc is produced by continuously

within tolerances established by the Metal framing Manufacturer's rolling steel coils or sheets through molten zinc at the mills. The coils

Association, Metal Framing Standards Publication No. MFMA-1. are slit to size and fabricated by forming, shearing or punching to

Material produce the finished product. During fabrication cut edges are not

generally zinc coated; however, the zinc near the uncoated metal

Steel used in the manufacture of Wesanco channels conforms to

the ASTM specifications in this catalog. becomes a sacrificial anode to protect the bare areas.

Design Paint-Green Powder Coating (GR)

A dark green low gloss powder coating is applied and thoroughly

Design is based on AISI "Specification for the Design of Cold-Formed baked after steel has been cleaned and phosphatized.

Steel Structural Members." Maximum bending stress used in design

is 25,000 pounds per square inch (PSI). This is based upon a virgin Hot Dip Galvanized After Fabrication (HG)

steel minimum yield stress of 33,000 PSI cold worked to an average Wesanco channel and fittings which are hot dip galvanized after

yield stress of 42,000 PSI. fabrication conform to one of the following specifications.

Welding ASTM A 123, ASTM A153 or ASTM A386.

Welds meet the performance requirements of section 4 of AISI Silva-Guard (SG)

"Specification for the design of Cold-Formed Steel Structural ZSi-Foster Silva-Guard coating is a multi-step process that meets

Members." All multiple sections of two or more single Wesanco the 1000 hour salt spray test per ASTM B117 and DIN 50021.Silva-

channels are resistance spot-welded approximately 2" to 3" on Guard coating is WEEE, ELV and RoHS compliant. SG Finish is

center. approved for outdoor as well as indoor applications. It is a chrome

free duplex coating system that combines an inorganic zinc-rich

basecoat with an aluminum-rich organic topcoat.

Special Coatings

Other commercially available finishes can be supplied per

specification when required to protect applications.

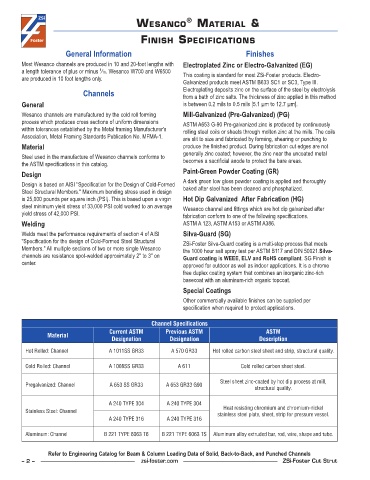

Channel Specifications

Current ASTM Previous ASTM ASTM

Material

Designation Designation Description

Hot Rolled: Channel A 1011SS GR33 A 570 GR33 Hot rolled carbon steel sheet and strip, structural quality.

Cold Rolled: Channel A 1008SS GR33 A 611 Cold rolled carbon sheet steel.

Steel sheet zinc-coated by hot dip process at mill,

Pregalvanized: Channel A 653 SS GR33 A 653 GR33 G90

structural quality.

A 240 TYPE 304 A 240 TYPE 304

Heat resisting chromium and chromium-nickel

Stainless Steel: Channel stainless steel plate, sheet, strip for pressure vessel.

A 240 TYPE 316 A 240 TYPE 316

Aluminum: Channel B 221 TYPE 6063 T6 B 221 TYPE 6063 TS Aluminum alloy extruded bar, rod, wire, shape and tube.

Refer to Engineering Catalog for Beam & Column Loading Data of Solid, Back-to-Back, and Punched Channels

– 2 – zsi-foster.com ZSi-Foster Cut Strut