Page 9 - ZSi-Foster Beta Hydraulic Clamps

P. 9

Beta Clamp Technical Data

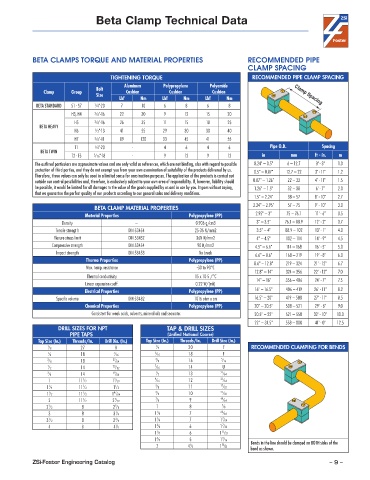

BETA CLAMPS TORQUE AND MATERIAL PROPERTIES RECOMMENDED PIPE

CLAMP SPACING

TIGHTENING TORQUE RECOMMENDED PIPE CLAMP SPACING

Aluminum Polypropylene Polyamide

Bolt

Clamp Group Cushion Cushion Cushion

Size Clamp Spacing

Lbf Nm Lbf Nm Lbf Nm

BETA STANDARD S1 - S7 1 ⁄4"-20 7 10 6 8 6 8

H3, H4 3 ⁄ 8"-16 22 30 9 12 15 20

H5 3 ⁄ 8"-16 26 35 11 15 18 25

BETA HEAVY

H6 1 ⁄ 2"-13 41 55 29 30 30 40

H7 5 ⁄ 8"-11 89 120 33 45 41 55

T1 1 ⁄4"-20 - 4 6 4 6 Pipe O.D. Spacing

BETA TWIN

T2 - T5 5 ⁄ 16"-18 - 9 12 9 12 in mm ft - in. m

The outlined particulars are approximate values and are only valid as references, which are not binding, also with regard to possible 0.24" – 0.5" 6 – 12.7 3' - 3" 1.0

protection of third parties, and they do not exempt you from your own examination of suitability of the products delivered by us. 0.5" – 0.87" 12.7 – 22 3' - 11" 1.2

Therefore, these values can only be used in a limited sense for construction purposes. The application of the products is carried out

outside our control possibilities and, therefore, is exclusively subject to your own area of responsibility. If, however, liability should 0.87" – 1.26" 22 – 32 4' - 11" 1.5

be possible, it would be limited for all damages to the value of the goods supplied by us and in use by you. It goes without saying, 1.26" – 1.5" 32 – 38 6' - 7" 2.0

that we guarantee the perfect quality of our products according to our general sales and delivery conditions.

1.5" – 2.24" 38 – 57 8' - 10" 2.7

BETA CLAMP MATERIAL PROPERTIES 2.24" – 2.95" 57 – 75 9' - 10" 3.0

Material Properties Polypropylene (PP) 2.95" – 3" 75 – 76.1 11' - 6" 3.5

Density – 0.906 g/cm3 3" – 3.5" 76.1 – 88.9 12' - 2" 3.7

Tensile strengt h DIN 53454 25-35 N/mm2 3.5" – 4" 88.9 – 102 13' - 1" 4.0

Flexure stress limit DIN 53452 36N N/mm2 4" – 4.5" 102 – 114 14' - 9" 4.5

Compressive strength DIN 53454 90 N/mm2 4.5" – 6.6" 114 – 168 16' - 5" 5.0

Impact strength DIN 53453 No break 6.6" – 8.6" 168 – 219 19' - 8" 6.0

Thermo Properties Polypropylene (PP) 8.6" – 12.8" 219 – 324 21' - 12" 6.7

Max. temp. resistance -30 to 90°C

12.8" – 14" 324 – 356 22' - 12" 7.0

Thermal conductivity 15 x 10-5 /°C

Linear expansion coeff. 0.22 W/[mk] 14" – 16" 356 – 406 24' - 7" 7.5

Electrical Properties Polypropylene (PP) 16" – 16.5" 406 – 419 26' - 11" 8.2

Specific volume DIN 53482 1016 ohm x cm 16.5" – 20" 419 – 508 27' - 11" 8.5

Chemical Properties Polypropylene (PP) 20" – 20.5" 508 – 521 29' - 6" 9.0

Consistent for weak acids, solvents, mineral oils and seawater. 20.5" – 22" 521 – 558 32' - 10" 10.0

22" – 31.5" 558 – 800 41' - 0" 12.5

DRILL SIZES FOR NPT TAP & DRILL SIZES

PIPE TAPS (Unified National Coarse)

Tap Size (In.) Threads/In. Drill Dia. (In.) Tap Size (In.) Threads/In. Drill Size (In.)

1 1 20 7 RECOMMENDED CLAMPING FOR BENDS

⁄ 8 27 R ⁄4

1 18 7 5 18 F

⁄4 ⁄ 16 ⁄16

3 18 37 3 16 5

⁄ 8 ⁄64 ⁄8 ⁄16

1 23 7 14 U

⁄ 2 14 ⁄ 32 ⁄16

3 59 1 13 27

⁄4 14 ⁄64 ⁄2 ⁄64

5

1 11 ⁄ 2 1 ⁄ 32 9 ⁄16 12 31 ⁄64

1

1 1 1 5 11 17

1 ⁄4 11 ⁄ 2 1 ⁄ 2 ⁄8 ⁄32

1 1 47 3 10 21

1 ⁄ 2 11 ⁄ 2 1 ⁄64 ⁄4 ⁄32

1

7

2 11 ⁄ 2 2 ⁄ 32 7 ⁄8 9 49 ⁄64

1 5 7

2 ⁄ 2 8 2 ⁄ 8 1 8 ⁄8

1

1

3 8 3 ⁄4 1 ⁄8 7 63 ⁄64

1 3 1 7 7

3 ⁄ 2 8 3 ⁄4 1 ⁄4 1 ⁄64

3

7

1

4 8 4 ⁄4 1 ⁄8 6 1 ⁄32

1 11

1 ⁄2 6 1 ⁄32

3 9

1 ⁄4 5 1 ⁄16 Bends in the line should be clamped on BOTH sides of the

1

2 4 ⁄2 1 ⁄32 bend as shown.

25

ZSi-Foster Engineering Catalog – 9 –